创新材料技术

-

催化技术

反应过程调控的核心技术

催化体系在高聚物合成过程中扮演着重要角色,根据目标高聚物的特点调整催化剂种类、配比、添加顺序等完成对整个合成反应的催化体系设计是瀚海创新材料开发过程中的重要技术能力。

另外,在工艺放大过程中,对催化工艺的精准把控也保证了产品生产过程的稳定性。

-

聚合物设计及改性

高性能聚合物开发的基础技术

瀚海作为以功能高分子材料为产品基础的创新型公司,聚合物的设计/改性、合成和生产能力体现了公司核心竞争力。依托于瀚海实验室聚合物研发平台,瀚海已经具备了从理论上的分子模型设计、性能预判、逆合成分析到实践上的配方设计、催化控制、反应放大等关键技术能力,保证了我们可以真正从客户需求出发进行聚合物的设计及改性。

-

粘结技术

胶黏复合材料的开拓性技术

丰富的粘结应用技术经验,让瀚海可以在客户粘结产品开发阶段,为其提供丰富的胶黏剂用高聚物选型咨询服务,满足客户对于各类粘接难题的挑战。

全面的粘结技术知识使瀚海能够利用全球技术专长为客户提供粘结领域解决方案。

-

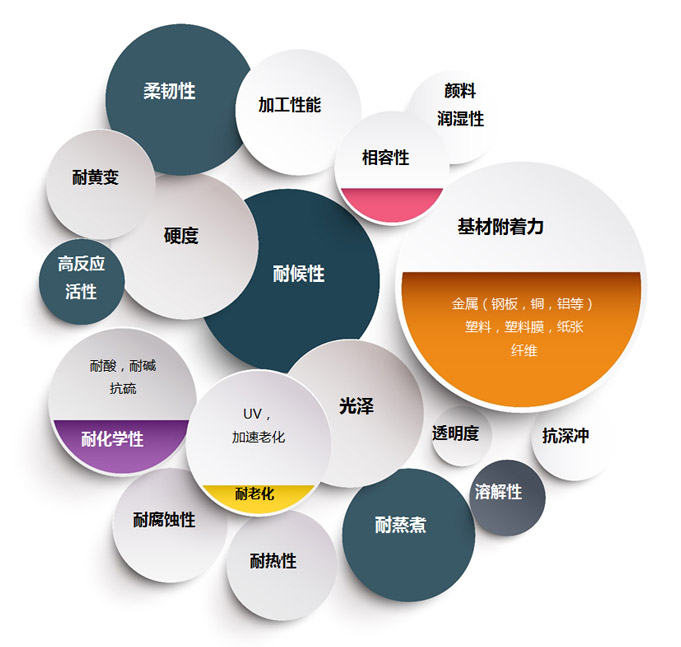

涂层技术

涂层应用性能探索的关键技术

瀚海自主搭建的涂层应用技术平台拥有对涂层多个维度应用性能的系统性评价能力。通过对涂层应用性能数据的不断积累,并结合产品参数的综合分析,瀚海建立了高聚物结构和应用性能的比对数据库,为聚合物的设计和改性提供了更完备的数据支撑。

瀚海以涂层技术专长为客户提供涂料涂层领域的整体解决方案。

- 市场/需求

- 性能设计/反合成分析

-

↓ 表征方法

↓ 测试技术

↓ 分析技术

- 分子设计

-

↓ 组分设计

↓ 结构设计

↓ 机理研究

- 合成设计

-

↓ 配方设计

↓ 催化体系

↓ 合成路线

↓ 实验装置

↓ 参数设定

↓ 控制设计

- 性能评估

-

↓ 检测技术

↓ 应用平台

- 产业化设计

-

↓ 中试技术

-

01UV光固化产品

UV光固化产品是产品中的光引发基团在吸收紫外光后,产生自由基,引发分子链之间的交联反应形成网状结构。这类产品只需要光固化,施工过程基本不使用有机溶剂,降低了VOC排放量。

-

02PUR热熔胶产品

PUR热熔胶,即湿气固化反应性聚氨酯热熔胶,是一类在加热熔融后涂布并借助空气中湿气交联固化的产品。与热熔型产品相似,由于整个过程没有有机溶剂的参与,产品更加环保。

-

03热熔型产品

瀚海Crysmelt™热熔型高分子量聚酯树脂是一类结晶型聚合物,与无定形类聚酯不同,这类产品在使用过程中不需要用到有机溶剂,可以减少甚至消除施工工程中VOC的排放量,是一类环境友好型产品。

-

04水溶性产品

瀚海Novoc™水溶性高分子量聚酯树脂,能够稳定的分散在水溶液中,直接应用于涂层、纺织等领域代替溶剂型产品。由于拥有溶剂型共聚酯相当的优越性能,被广泛用于环保要求严苛,同时对性能需求较高的项目中。

-

05高固低粘产品

瀚海高固低粘类型树脂产品能够以较高的固体份溶解在有机溶剂中,仍然保持较低的粘度和良好的施工性能。由于溶剂含量低,减少了烘烤等过程中挥发性有机化合物(VOC)的排放量,减轻了溶剂型产品对生态环境的压力。